RAPID DEPLOYABLE BUILDING SYSTEMS

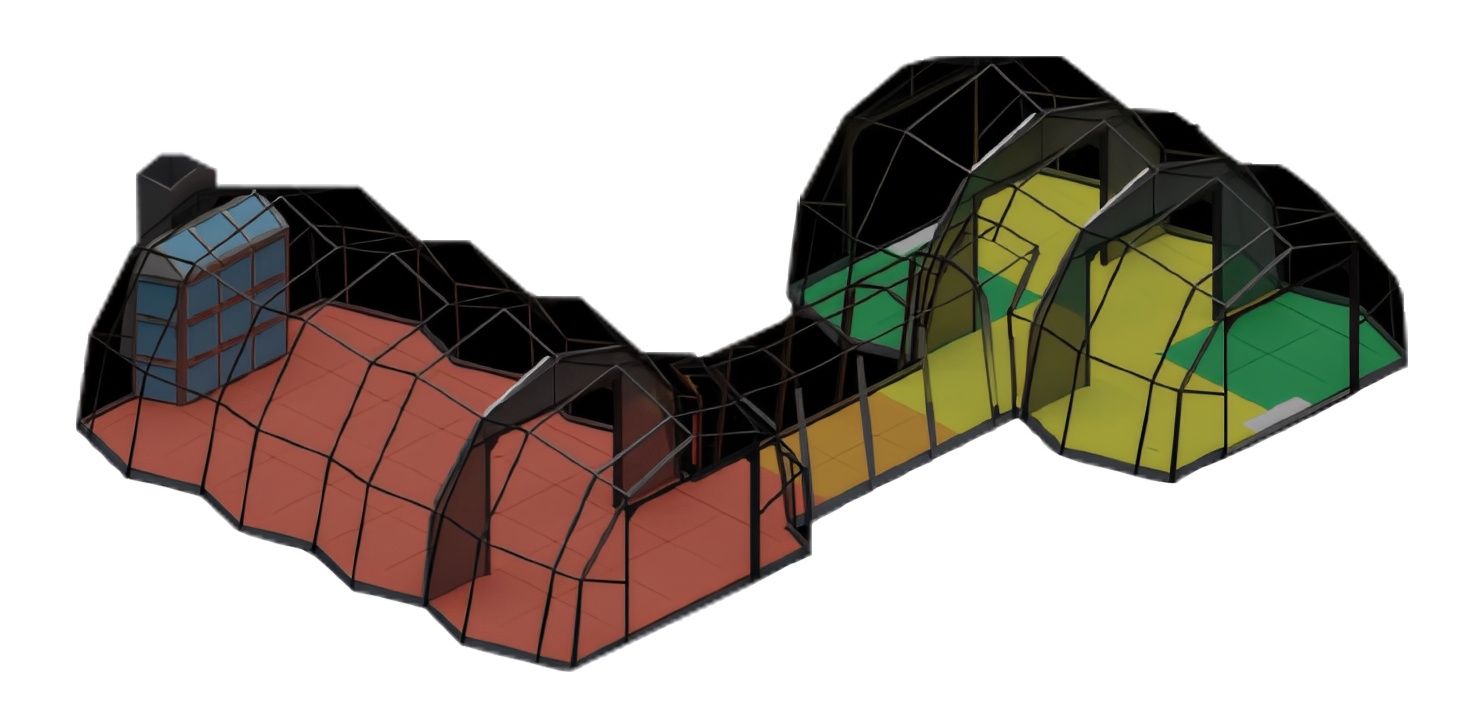

The Advanced Deployable Aircraft Mobile System (ADAMS) is a relevant, game changing approach to rigid walled deployable structures.

The fabrication, composite repair and low observable coating restoration shelter is a “first of its kind” rapidly deployable kit. The ADAMS maintenance complex solution is an achievement that is unmatched to date. Ready to provide prepositioned war reserves, and post attack or natural disaster recovery stop gap operations anywhere in the world.

Use Cases

Standard Shelter

The Exohab is the backbone of the Trac9 family of shelters. It is the first-of-its-kind hybrid shelter system capable of meeting facility demands in a foldable, expandable, rigid composite solution.

Packaged with a standard split air conditioning and heating unit, it can be shipped on a standard aircraft pallet, ISU-90, or other containerized solutions. The Exohab is ready to meet any use case demand.

Paint Complex

Advanced 5th Generation Fighter Aircraft and unmanned platforms require a climate-controlled solution to repair advanced composite structures and apply protective coatings closer to the point of need.

Vast geographical mission demands for providing combat-ready aircraft all over the world require a system to prevent shipping critical parts and components stateside. To increase logistics lethality, Trac9 has developed a deployable solution preventing delayed discrepancies for composite and low observable-based platforms.

Additive Manufacturing

The ADAMS creates an environment where climate control can be maintained in a ruggedized insulated shelter system with the ability to grow as your demands and mission expand.

Think of it as a platform in which to plug and play software, computers, monitors, 3D printers & scanners and post processing equipment to deliver and bed down technology anywhere in the world.

Expeditionary Medical Facility

Step into the future of combat medical care with a system that can transform to meet any standard clinic or surgical center needs. Whether you require additional surge capacity or are looking for an austere location medical suite.

The composite structure can be outfitted with divider walls for privacy or can complex to additional shelters to create an entire medical compound. Suspend lighting, dental, X-ray or any other medical equipment from the roof of the structure to fit your mission requirements.

Aircraft Maintenance

The ADAMS was developed to suit the unique demands of the aircraft maintenance community. The system can be utilized as a plug and play unit with the ability to complex an ISU-90 full of tooling or other aviation equipment to rapidly setup positive tool accountability within a few hours of arrival.

Whether you are prepositioning an ADAMS for a rainy day or looking to take it on a deployment, we can tailor package this solution to meet your in garrison or deployment requirements.

Disaster Relief

Trac9’s systems stand ready to provide viable shelter solutions capable of meeting high wind and snow load demands. Whether you need a solution to house displaced families following a natural disaster or need additional office or modular facility space, we are here to assist.

The system’s composite rigid design gives it the ability to be stored long-term in preparation as war reserve material solutions, post-attack or disaster relief assets.

Standard Shelter

Paint Complex

Additive Manufacturing

Expeditionary Medical Facility

Aircraft Maintenance

Disaster Relief

Standard Shelter

This hybrid system is the future of the mobile maintenance facility (MMF), requiring half the packed space and double the square footage as compared to traditional MFF’s. It provides the ability to expand your mission and equipment demands without being confined to a non-expandable box or platform. Our state-of-the-art arch systems can be complexed to one another or added to extend your available workspace options.

- Self-contained, transport-ready

- Packed and shipped on one pallet position

- Rigid panelized structure – Efficient and secure

- 1/3 the packed volume and 2x the deployed area of a typical ISO container shelter

- Setup by 4 personnel in 40 min, on any type of site with no additional equipment required

ADAMS – LO+ PAINT COMPLEX

This is the first complete packaged system capable of meeting facility requirements in a deployable kit. Our modular paint system provides a stop gap solution for existing facility downtime or maintenance. It can also be utilized as a surge capacity for small aircraft parts or even refurbishing Aerospace Ground Equipment. The system was built in close coordination with USAF Aircraft Structural Maintenance and Bioenvironmental experts to ensure proper worker decontamination processes are met.

ADAMS Container Covers

Covers and ISU-90 containers complex to ADAMS Shelters with vented design 4 removable door panels and integrated tie downs.

- ISU-90 and 463L pallet cargo cover Sold seperately or provided with ADAMS shelters

- 1 person installation in 5 minutes

- Water proof, UV resistant, PVC coated textile with seam welded construction

- Reduces corrosion by 80-90% with high moisture removal rate Antimicrobial material properties to control mold and mildew